How to Choose the Correct Propeller for Your Outboard?

The right prop will get the best performance out of your boat, and it also increases the lifespan of your engine. Matching the propeller to your boat application, whether cruising, water skiing, or performance, maximizes the power from your outboard engine. It also helps with handling and acceleration.

Use this guide to learn how different propeller designs affect efficiency, power, and speed, and then learn how to choose the correct prop for your boat and application.

Here are tips, straight from the experts!

1. Know the Basics of Propeller

While initial propping for new boats is often spot on, increases in boat weight over time might call for an upgrade. Choosing the right outboard propeller can be perplexing, but it doesn’t have to be. Selecting the right propeller is part guesswork and part science.

To home in on the science side, the top experts in the marine industry for their best tips on choosing the right prop for your boat-and-outboard combination.

The panel included Gary T. Diehl (GD), Mercury Marine’s senior category manager for props and gauges; David Meeler (DM), Yamaha Marine’s product introduction and information manager; and David Greenwood (DG), Suzuki Marine’s general manager for the Marine Technical Center USA. and Ashlyn McGuire from Marine Parts Warehouse Here is what they had to say.

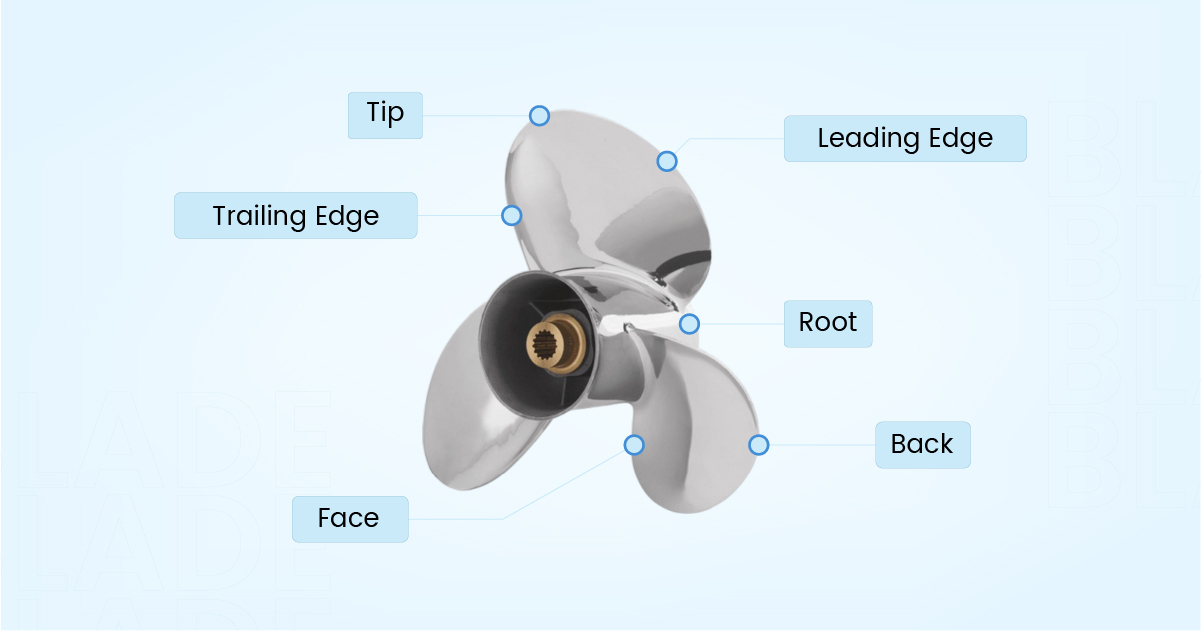

First, know the terminology of the propeller:

- Back - the low-pressure side of the blade closest to the boat

- Cavitation - vaporized air caused by water flow disturbances

- Cup (blade) - the lip on the edge of the blade. Diameter- width of the circle made by the tips of the blades. Face (blade)- the high-pressure side of the blade farthest from the boat

- Leading Edge (blade) - the blade edge closest to the boat

- Pitch - distance travelled by the propeller in one revolution

- Rake - angle between the blade and the hub

- Root (blade) - the edge of the blade attached to the hub

- RPM - revolutions per minute

- Slip - distance lost due to inefficiency

- Surface Area - the total surface of the blades

- Tip - the point separating the leading edge and trailing edge farthest from the hub

- Trailing Edge (blade) - the blade edge farthest from the boat

- Ventilation - air bubbles surrounding the blades

- WOT - wide open throttle

Check out These New Outboard Propellers For Your Boat

- Mercury & Mariner Propellers & Hub Kits

- Johnson & Evinrude Propellers & Hub Kits

- Chrysler & Force Propellers

- Honda Propellers & Hub Kits

- Suzuki Propellers & Hub Kits

2. Dialing in Pitch and Diameter

In propeller designation, diameter is the first number listed, followed by pitch. To calculate the propeller size, measure the diameter across the outer circle of the blade tips, while pitch is the distance a prop theoretically moves forward in a single revolution. So, a 15x17x3 designation indicates a 15-inch diameter and 17-inch pitch with three blades.

In most cases, the boat propeller and outboard manufacturers have pre-selected the diameter range needed for your engine. Your selection can be focused almost exclusively on pitch. Your vessel will respond to different pitches the way your car responds to different gear positions in your car's transmission.

But keep this in mind when changing propellers, “Diameter can have as much impact as pitch,” McGuire explains. “All things being equal, one-quarter inch in diameter equals the same 150 rpm change associated with pitch. That’s because of the blade surface area. A larger diameter increases the blade surface, which contacts more water.

But it’s also more difficult for the engine to move the prop as the diameter increases. That’s why in a family of propellers, as the pitch increases, the diameter generally decreases.” A propeller only performs when water is on the blade.

3. Rake and Blade Design

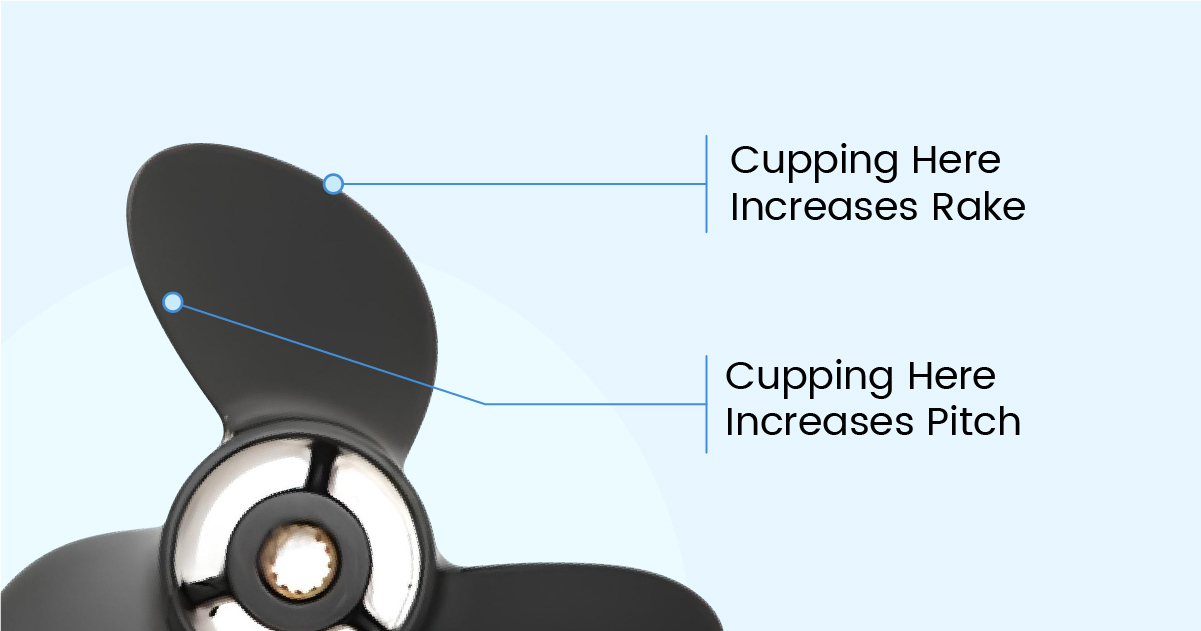

Blades have other important features built into their design. Rake is the angle between the blade and the hub. The rake angle can be flat, staying the same along the entire blade, or progressive, meaning the angle increases as it approaches the tip.

Props have between 0 and 20 degrees rake. The rake angle determines how much the bow lifts out of the water. High rake propellers are ideal for lightweight, high-speed boats. Too much rake, however, will strain the engine and reduce overall performance.

So consider the shape, angle, and number of blades. McGuire uses the image of a two-by-four to illustrate the concept of rake. Sliding the board through the water, skinny side first, is easy. But trying to push it through on the flat side is much more difficult. Having a lot of rake is similar to pushing against the flat side of the board.

Conversely, the quicker the engine spins up (the less the rake), the faster the boat moves through the water. Moving to a higher pitch will result in a decrease in your full-throttle RPM, just like the effect when your car's transmission shifts to a higher gear.

The reverse is also true: move to a lower pitch and your full-throttle RPM will increase. Most propellers are sized by two-inch intervals, for example, 17", 19", 21", etc, and a 2" pitch change will result in an average 300 to 400 full-throttle RPM change.

4. Pitch: Matching RPM to Use

Pitch is the distance the propeller will move the boat after one revolution (not accounting for slip). A lower-pitched propeller will create more power due to more engine RPMs, but the boat will move more slowly. A higher-pitched prop allows the boat to move faster by travelling a farther distance with each rotation.

When choosing a propeller, choose a pitch that will keep the engine RPM in its recommended operating range. Going under the range will cause the boat to lug, while going over can cause engine strain.“There is no perfect propeller that does it all,” says David Meeler, Yamaha Outboards' propeller information manager. “There are too many variables in boat design and performance. Each propeller is a compromise. You have to give up a little of one aspect, such as top speed, to get more of another, like acceleration.”

Read how you can repair your propeller yourself.

The optimum boat propeller for your particular application is one that will allow your boat's engine - with your normal load aboard - to develop full-throttle RPM within the engine manufacturer's recommended maximum RPM range.

DM: Each inch of the pitch will affect engine speed by 150 to 200 rpm. As the pitch goes up, rpm goes down. When the diameter goes down, rpm rises. Each one-quarter inch in diameter has the same effect. A boat should be propped to where it’s properly trimmed out, and the wide-open throttle (WOT) rpm is in the top 30 percent of the manufacturer’s acceptable WOT rpm range with the average load in the boat.

5. Blade Cupping: Grip and Efficiency

Cup, the curling or bending of the blade tips, will also impact performance because shape influences how water comes off the blade. Cupping can add grip and enhance bow rise, but too much can add drag. With a cup, like a rake, a happy medium is usually the best combination.

6. Recommended RPM: WOT and Engine Health

Outboards have a recommended WOT (Wide Open Throttle), and the right prop keeps the engine in that sweet spot. The wrong propeller causes the engine to labor or over-rev, shortening its life and decreasing performance.

Learn how you can detect the spun-outboard propeller hub.

Damage to the engine can occur if a propeller that allows the engine to over-rev (attain a full-throttle RPM higher than the specification) is installed. Damage can also occur if the installed boat prop causes the engine to lug, not reach the minimum specification.

Overall best acceleration and top-end speed will be achieved when your full-throttle RPM is near the midpoint of the manufacturer's recommended maximum RPM range.

7. What Propeller Material is Best? Aluminum or Stainless

Deep water is typically safe for aluminum, while you’d want to stick to sandy spots in shallow water unless you’re running a stainless steel propeller on your watercraft. Both have different advantages and situations to use them in.

An aluminum propeller is sufficient for most boats, with only boats that demand the best quality, performance, and top speed often rating a stainless steel propeller. Get a short comparison to choose the best for your boat.

| Feature | Aluminum Propellers | Stainless Steel Propellers |

| Performance | Adequate for casual boating, light fishing, and deep water; lighter weight helps acceleration and fuel efficiency | Superior performance, thinner rigid blades flex less, reduce drag, improve top speed, hole shot, and fuel economy |

| Durability & Damage | More prone to blade flex and damage; absorbs impacts by bending or breaking, protects drivetrain | Highly durable, withstands impacts, resists flex; less likely to damage blades, but rigid, so impacts can transfer to the gearcase |

| Repairability & Spares | Easy and low-cost to repair with basic tools; ideal as a spare prop on board | Repairs are more complex and costly; they are often worth repairing rather than replacing the bulky stainless part |

8. Blade Count: 3, 4 or More Blades

DM: Many boaters say, “I never run wide-open, so what does it matter?” It matters because, otherwise, you don’t know if the boat is wasting rpm and not giving total available speed (not enough prop) or if it is pushing too hard and the engine is lugging (too much prop).

DG: The most common mistake occurs when the boat gets propped correctly initially, then owners add extras onto the boat over time, and now the rpm and hole shot are greatly affected when the boat has a lot of passengers.

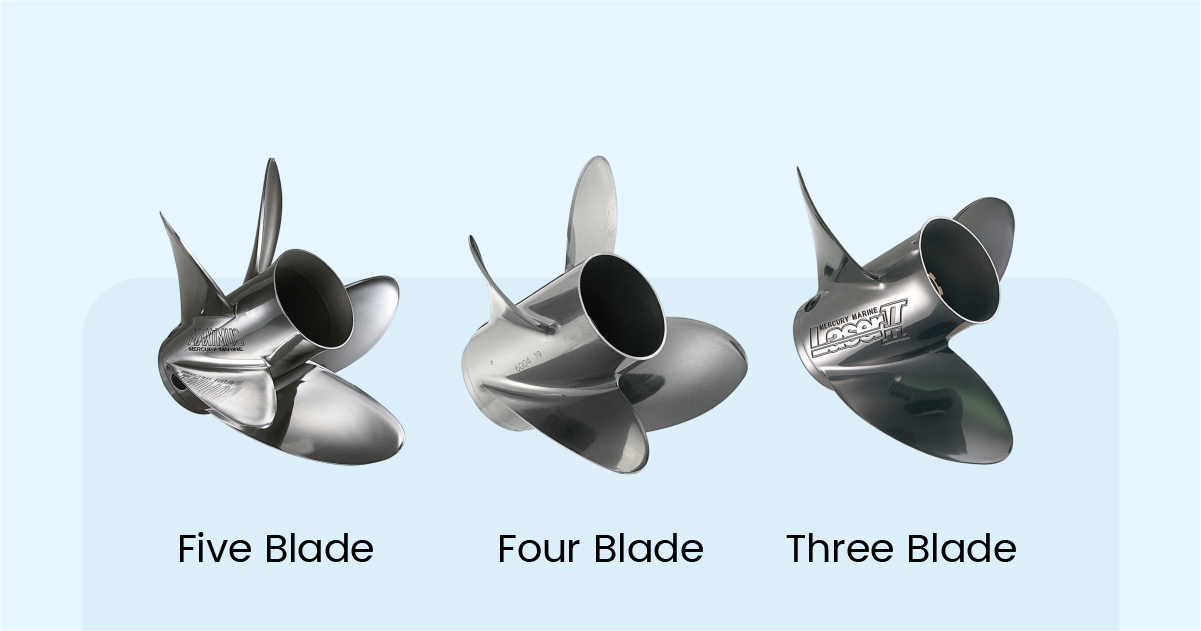

Three Blades Props

Three-bladed props, the most common configuration, are the most efficient. They spin up faster and produce less drag.

3-blade props are perfect for recreational boats. They’re especially good for boats with 3, 4, and 6-cylinder outboard and I/O engines. Fewer props allow for a higher top speed but less horsepower. Since recreational boats are often lighter, you aren’t losing a lot. You’ll be able to achieve a higher speed and have more fun on the open water.

Four Blades Props

Four blades aid initial acceleration and stern lift, advantageous for flats boats in skinny water or the center engine in a triple setup.

When to Go With Four-Blade Props?

- DM: Four blades are specialty props and should be used when your boat needs extra load-carrying capacity, maximum hole shot, and better control in rough water.

- DG: One caution about four-blade props is that they tend to create stern lift that can drive the bow down and make the boat run too level.

The Right Prop for Varying Loads

DM: This is the ideal situation for owning two propellers, one to address each scenario. However, if only one prop is used for two widely disparate applications like this, I would prop for the heavy application. Lugging a marine engine is more damaging over time than running it light.

DG: I would prefer the boat to have good or acceptable performance with a lot of people. When the hole shot is poor, everyone remembers it. Compromise by not using full-throttle movement and staying out of the rev limiter.

GD: Prop the pitch selection at the very top end of the recommended engine rpm when you are in a light-load condition, and hope that the engine is still within the recommended rpm range when operating heavy. If the WOT engine rpm ends up below the recommended rpm in a heavy payload condition, lower the pitch to prevent engine lugging.

Five Blades Props

Five-bladed props are top performers in rough conditions or when torque and acceleration are priorities.

Adding a fifth blade further increases blade area, reduces vibration, and improves the prop’s ability to hold its grip on the water. The five-blade design allows it to maintain a solid bite on the water, even in the highly aerated water flow produced by performance boats with stepped hulls.

The total number of propeller blades will also impact overall performance and top speed. Fewer blades are more efficient. Again, the choice must be balanced against the performance objectives, boat design, and normal use.

Consult engine performance bulletins for your boat model and dealer recommendations before making a final propeller decision. If necessary, have a prop shop fine-tune them some more after extensive testing under normal loads and conditions.

And remember: Dialing in a propeller is an art, not an exact science. Explore for more propellers and outboard engine parts.

FAQs

Is a 19 or 21 Pitch Prop Faster?

A 21-pitch prop is faster at top speed but needs more engine power. A 19-pitch prop offers better acceleration and pulling power but slightly lower top speed.

Can the Wrong Propeller Affect Fuel Efficiency?

The wrong propeller can reduce fuel efficiency. It may cause the engine to work harder or run outside its optimal RPM range, increasing fuel consumption and wear.

How Can I Tell if it Might Be Time to Get a New Prop?

Check for cracks, bent blades, vibration, or decreased performance. If your boat struggles to plane or burns more fuel than usual, it's likely time to replace the prop.

The Bottom Line

Your boat runs best when the propeller is right for it. It’s that simple. Smooth handling, quicker starts, and better gas use all depend on this one thing spinning at the back. A lot of people keep using a prop that is close enough. That choice can turn a fun trip into a rough one. The small part spinning below can be the reason your trip is either fun or frustrating. Take a little time, look at your setup, and don’t be afraid to switch things up. Try one, feel it out. You’ll know when it clicks. Your engine will run smoothly.

Posted by Shooter Mcgavin