Essential Parts of an Outboard Engine - Their Functions and Maintenance

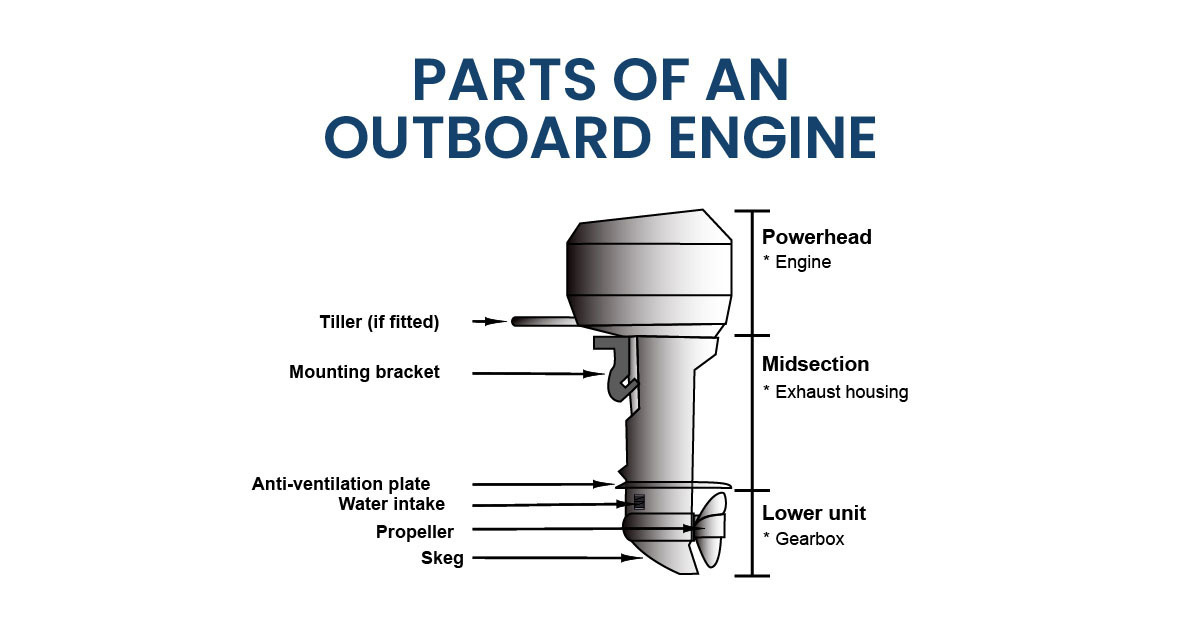

Understanding the parts of an outboard engine is essential for anyone involved in boating, whether you are a recreational user or a professional. Outboard engines are complex machines designed to deliver power, performance, and reliability on the water. Key components include the powerhead, which generates the engine’s power; the midsection, which houses the exhaust system; and the lower unit, which contains the gearbox and propeller.

Each part plays a critical role in ensuring smooth operation and optimal performance. Modern outboard engines also feature advanced components like electronic control modules (ECMs) for precise performance management and cooling systems to prevent overheating.

In this blog, we’ll explore the anatomy of an outboard engine in detail, helping you understand how these parts work together and offering maintenance tips to keep your engine in top shape.

9 Parts of Outboard Engine and Their Features

1. The Powerhead: The Heart of Outboard Engine

The powerhead is the center of an outboard engine, containing the motor square, cylinders, barrels, and ignition system. It is responsible for producing control through combustion.

Shop Remanufactured OBR / Yamaha 1996-2009 150 HP V6 2.6L Powerhead

The fuel-air blend is touched off on the powerhead rebuild, causing blasts that move the cylinders up and down. This movement turns the crankshaft, which gives control to the propeller. The proficiency of the powerhead straightforwardly impacts the engine's execution, influencing everything from speed to fuel utilization.

Normal support, counting convenient oil changes, and checking the start plugs make a difference in keeping the powerhead running easily, expanding the engine's life expectancy, and optimizing performance.

Read the full Review of Outboard Powerhead Rebuild Kits

2. Lower Unit: Where Power Meets the Water

The lower unit connects the detachable motor to the propeller and contains vital components such as the gearbox, driveshaft, and propeller shaft. It is dependable for changing the rotational control produced by the motor into a push to move the watercraft.

The lower unit, moreover, houses the gearcase, which empowers the motor to go forward or turn around. Appropriate upkeep of the lower unit, including checking the oil and greasing up the moving parts, is imperative for smooth operation without a well-functioning lower unit.

3. Propeller: Converting Engine Power to Thrust

The propeller is a key component of an outboard motor; this part is responsible for converting the rotational energy into forward movement. When the motor turns the propeller, the edges thrust water behind the watercraft, making a push that impels it forward or in reverse. Propeller measure, shape, and pitch influence the boat's speed, fuel productivity, and dealing with.

Choosing the right propeller for your motor and sculling needs guarantees ideal execution, making a difference in your spare fuel and progress maneuverability. Standard assessment for harm or wear is fundamental for proceeding function.

4. Exhaust System: Keep Your Engine Running Smoothly

The exhaust system in an outboard engine expels the gases produced at some point of combustion. It regulates engine temperature by permitting the exhaust gases to go out, stopping them from overheating the engine.

Normally, in outboard engines, the exhaust device vents via the lower unit, assisting in cooling the engine as the boat actions. It also minimizes engine noise and decreases environmental pollution.

The exhaust machine can also collect carbon deposits through the years, affecting engine performance. Recurring inspection and maintenance are critical to make sure the exhaust system works effectively, stopping engine overheating and extending the engine’s lifespan.

5. Cooling System: Protecting Your Engine from Overheating

The cooling system in an outboard engine plays a vital role in stopping overheating. Most outboard motors use a water-cooling machine, where water is drawn from the lake, river, or sea and handed through the engine to take in heat.

The cooled water flows out of the engine, keeping the most desirable working temperature. The gadget consists of a water pump, thermostat, and cooling jackets that ensure proper water drift and temperature laws.

Without a functioning cooling gadget, an engine can overheat, main to high-priced maintenance or even everlasting harm. Ordinary renovation, together with cleaning the intake display, is vital for dependable cooling.

6. Steering System: Controlling your Boat Directions

The steering system permits the operator to control the direction of the boat. In an outboard engine, the gadget lets you show the outboard motor, which changes the boat’s course. Steerage is generally controlled by a wheel or handlebars related to cables or hydraulic components that pivot the engine.

The system ensures that the outboard engine responds precisely and steers the boat appropriately when you turn the wheel or handles.

A nicely maintained steering system is vital for secure navigation. Issues like stiffness or unresponsiveness can arise from worn cables or hydraulic troubles, requiring set-off upkeep.

7. Electrical System: Powering the Engine’s Function

The electrical machine of an outboard motor powers critical features, consisting of ignition, sensors, and lights. It includes a battery, alternator, wiring, and the manipulate panel. The battery presents the preliminary strength to start the engine, while the alternator recharges it because it runs.

The electric engine also supports the ignition process by presenting energy to the spark plugs and using different additives. Right maintenance of the electric machine guarantees dependable performance, especially whilst you’re out on the water.

Frequently checking connections, examining wires for damage, and ensuring the battery is charged can prevent inconvenient breakdowns and electric screw-ups.

8. Fuel System: Ensuring the Engine Gets the Right Fuel

Fuel system in an outboard engine is responsible for delivering the best amount of fuel to the engine for combustion. It consists of components like the gasoline tank, gas lines, filter out, and carburetor or gasoline injectors.

A carburetor that supplies a spark-ignition engine with a mixture of fuel and air. Components of carburetors usually include a storage chamber for liquid fuel, a choke, an idling (or slow-running) jet, a main jet, a venturi-shaped air-flow restriction, and an accelerator pump.

Fuel from the tank flows through the traces and is filtered to ensure cleanliness before entering the carburetor or gasoline injectors.

The outboard carburetor or injectors mix the gas with air before it enters the combustion chamber, where it is ignited to generate power. maintaining the gas gadget is crucial for the most advantage

9. Trim and Tilt System: Optimizing the Engine Position

The trim and tilt device on an outboard engine lets you regulate the engine's function to enhance overall performance and management. The trim feature adjusts the engine’s working performance to the boat’s hull, optimizing the boat’s pace gasoline performance and coping primarily based on water conditions.

The tilt function lets you raise the engine for simpler docking, shipping, or while navigating shallow waters. Both capabilities can be controlled manually or with hydraulic assistance, relying on the motor. Retaining the trim and tilt device properly is essential for preserving engine health and optimizing your boating experience in numerous situations.

Advanced Features in Modern Outboard Engines

Modern outboard engines are engineered with advanced technologies that enhance their performance, efficiency, and user experience. These innovations set new standards for power and reliability, making them indispensable for boaters.

Electronic Control Modules (ECMs): Electronic Control Modules (ECMs) act as the brain of modern outboard engines, managing various systems to ensure precision and efficiency. ECMs regulate fuel injection, ignition timing, and engine diagnostics, optimizing performance based on real-time data. This ensures smoother operation, reduced emissions, and greater reliability.

Direct Fuel Injection: Direct fuel injection technology has revolutionized fuel efficiency in outboard engines. By delivering fuel directly into the combustion chamber, this system improves fuel atomization, reduces waste, and increases power output. The result is better mileage and a more eco-friendly boating experience without compromising performance.

Noise Reduction and Vibration-Dampening Technologies: Modern outboard engines prioritize user comfort with advanced noise reduction and vibration-dampening systems. These technologies minimize engine noise and vibrations, providing a quieter, smoother ride. Features like insulated housings and innovative mounting systems enhance comfort, making boating more enjoyable for passengers and operators alike.

These advanced features not only improve the functionality of outboard engines but also elevate the overall boating experience by combining power, efficiency, and comfort.

How to Maintain Your Outboard Engine for Longevity?

Preserving and properly repairing your outboard engine is important for ensuring its longevity and ultimate overall performance.

- Start by frequently converting the engine oil and checking the gasoline machine for leaks or clogs.

- Clean the air, clear out, and look into the spark plugs to ensure proper ignition.

- Preserve the cooling system in check by flushing the engine with clean water after every use to save you salt buildup.

- Lubricate the decreasing unit's moving elements, and check out the propeller for damage.

- Regularly take a look at the electrical system, battery power pack, and connections.

- Constant upkeep helps save you expensive maintenance and maintains your outboard motor running easily for years.

Learn How to Determine the Year of Your Outboard Engine

FAQs

What is the lifespan of an outboard engine with proper maintenance?

With proper care and regular maintenance, an outboard engine can last between 1,500 to 3,000 hours of operation or more, depending on usage and conditions.

How often should I replace the spark plugs in my outboard engine?

Spark plugs should typically be inspected every 100 hours or annually, whichever comes first. Replace them if they show signs of wear or poor performance.

Can I upgrade my outboard engine’s components for better performance?

Yes, you can upgrade specific parts, such as propellers, fuel systems, or electronic controls, to enhance performance, fuel efficiency, or overall reliability.

How do I know if my outboard engine’s lower unit needs servicing?

Signs like grinding noises, difficulty shifting gears, or leaking gear oil may indicate that the lower unit requires servicing or repair. Regular inspection can prevent major issues.

How can I reduce noise and vibration from my outboard engine?

You can reduce noise and vibration by upgrading to modern vibration-dampening mounts, using insulated housings, and ensuring the engine is correctly aligned and maintained.

Conclusion

Understanding the essential parts of an outboard engine is not just about enhancing your boating experience—it's about ensuring the longevity and reliability of your vessel. By knowing how each component functions and staying on top of regular maintenance, you can enjoy smoother rides and avoid unexpected breakdowns.

Ready to put your knowledge into action? Whether you’re looking for replacement parts, upgrades, or accessories, OB Parts has everything you need.

From precision-engineered components to maintenance kits designed for convenience, our collection is tailored to keep your engine running at its best. Don’t let wear and tear slow you down. Browse our curated selection of outboard engine parts today and invest in the performance your boat deserves. With the right tools and a little care, you’re set for countless adventures on the water!

Posted by Brian Whiteside