What Other Uses Are There for a Jet Drive?

Jet drives are most commonly associated with high-speed boats and personal watercraft, but did you know they have many other uses beyond just marine propulsion? From military vessels to environmental rescue operations, jet drive technology has proven to be incredibly versatile.

In fact, jet drives are known for their efficiency, maneuverability, and ability to operate in shallow waters, making them ideal for a wide range of industries. Have you ever wondered how jet drives are transforming fields like underwater exploration or even luxury watercraft?

In this article, we will explore the surprising and diverse applications of jet drive technology across various sectors, showcasing its growing importance in modern technology.

How Do Jet Drives Work?

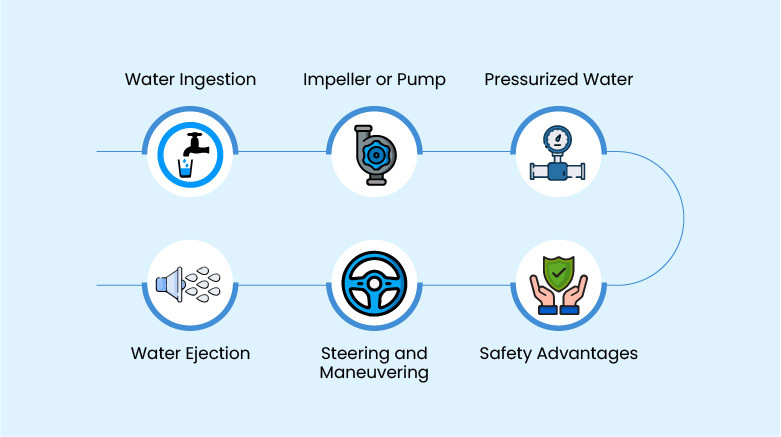

A jet drive is the form of propulsion used by a boat or watercraft to push themselves in the water. This can work by taking in water and pushing it out at high speed, allowing them to move forward. So, how do jet drives actually work? Here’s a breakdown of how jet drives work, step by step:

1. Water Ingestion

The process of water being sucked into a boat is through an intake located at the bottom of its hull. The intake is placed in a way that receives a large amount of water as the boat moves along.

Why it matters: The speed of the boat determines how much water would be taken in to produce a greater thrust used to push the boat out.

2. Impeller or Pump

When water reaches the intake, it is directed towards the impeller, a form of pump, inside the jet drive unit. The impeller is a spinning rotor often made of metal or plastic, which rapidly moves water.

How it works: When the impeller rotates, it forces the water into a narrow channel where it increases its speed. The faster the impeller rotates, the more water that is pushed through to create more thrust.

3. Pressurized Water

Once the impeller speeds up the water, it moves into a volute (a spiral-shaped casing) that helps to direct the high-speed water flow into a nozzle. The water is now pressurized and traveling fast.

Why it's important: This is why the water in the boat can quickly propel the boat forward since pressure and speed make water travel far like a hose if you have the nozzle constricted.

4. Water Ejection

The water is forced out through a nozzle at the back of the boat, but this time, the nozzle is usually adjustable in many systems. The direction of the flow of water is used by the operator to steer the boat.

Outcome: At high speed, the exit of the nozzle forces the water backward. It thus pushes the boat forward.

5. Steering and Maneuvering

In most jet drive systems, the nozzle can be tilted or rotated to steer the boat. The operator can control the direction of the jet stream, allowing for precise turns and quick maneuvering. This is a key advantage of jet drives over traditional propellers.

Why it's cool: Jets can be turned by opening the nozzle, thereby turning the thrust-producing component. They are very sensitive to direction of thrust and wonderful at doing tight turns, making them useful in high-speed or low-speed operations in shoal water, where propellers may not function properly.

6. Safety Advantages

Unlike traditional propeller boats, jet drives are safer because there is no exposed spinning blade that can harm people or objects in the water. Intake and nozzle are usually covered by a grating or cover to reduce the risk of injury.

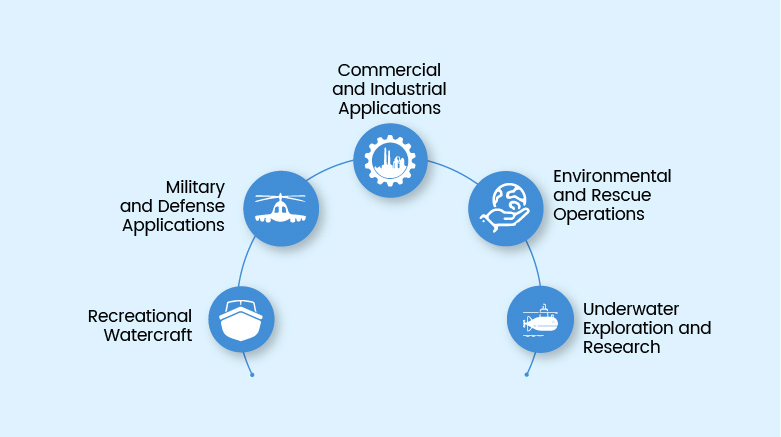

5 Key Uses of Jet Drives in Various Industries

Jet drives are versatile propulsion systems that have found applications in many industries beyond traditional watercraft. Here are five key areas where jet drives are being used:

1. Jet Drives in Recreational Watercraft

Jet drives are commonly used in personal watercraft such as jet skis, wakeboards, and small boats. These watercraft use the jet drive's power to provide fast acceleration and maneuverability.

Why They Are Popular: One major benefit of jet drives on leisure boats is that they work even in shallow waters without exposing the propeller and the damage it could potentially take. They also afford superior control and are more safe because they don't expose blades.

Facts and Figures

- Jet skis reach a speed of as much as 65 mph, or 105 km/h, due to jet propulsion.

- Jet drive-powered boats are very ideal for watersports like wakeboarding. It makes response faster and handling smooth.

- Jet-driven watercraft can operate in just 6-12 inches of water, making them great for shallow areas.

- Jet drives have no exposed propeller, reducing injury risks. New jet drive models are quieter and meet stricter noise regulations.

2. Jet Drives in Military and Defence Applications

Jet drives are used for fast assault boats, amphibious vehicles, and reconnaissance vessels in the military. The boats must be speedy, agile, and must operate in shallow waters.

Why Its useful: Jet drives provide military vessels the capacity to attain high speeds, still managing stealth due to the noise levels lower than traditional propellers. Also, the launch time is quite faster, and navigating shallow territories such as marshes or rivers is very easy.

Facts and Figures

- Jet drives provide for rapid transitions between land and water, perfect for amphibious assault vehicles.

- Jet drives are not noisy and can be stealthy because of their silence, which can never be detected easily.

- It uses jet-driven rescue boats to quickly get out of flooded regions or hostile terrains.

- Jet drive boats are manufactured to withstand aggressive conditions, so they do not hesitate to operate when extreme weather or rough sea conditions arrive.

3. Jet Drives for Commercial and Industrial Applications

Jet drives are also used in large commercial vessels, including ferries, cargo ships, and passenger boats. Their usage includes industrial watercraft such as dredgers and service boats.

Why It Matters: Jet drives provide better fuel efficiency and maneuverability, especially in congested or confined spaces like ports or narrow channels. They also reduce the chances of getting damaged by underwater obstructions.

Facts and Figures

- Jet drives can be efficient during dredging operations to push through shallow and debris-laden waters, something that propeller-driven boats could not do.

- Industrial boats, such as dredgers and tug boats, use jet drives primarily for better maneuverability while operating in busy harbors.

- Jet drives are preferred in demanding commercial and industrial conditions due to their ability to operate reliably in harsh weather and rough waters.

4. Jet Drives in Environmental and Rescue Operations

Jet drives are used for rescue boats and environmental monitoring vessels. Its ability to navigate in shallow and challenging water makes it ideal for search-and-rescue missions, oil spill responses, and environmental surveys.

Why It Matters: Jet-drive boats can go faster and navigate into narrower spaces than other types of boats to reach disaster zones in emergency situations. In addition, they are used for oil spill recovery because they avoid sensitive ecosystems.

Facts and Figures

- In the case of oil spill response, jet drive-powered boats can operate at a water depth of as little as a few inches, which makes them ideal for reaching contaminated shorelines.

- Rescue operations in flood-prone areas often employ jet-powered boats to navigate flooded streets or marshlands, saving time compared to traditional vehicles.

- Sharp turns and rapid direction changes are crucial in rescue operations, particularly in crowded or narrow waterways.

5. Jet Drives for Underwater Exploration and Research

Jet drives are also used in Remotely Operated Vehicles and Autonomous Underwater Vehicles. They are deployed by scientists for deep-sea exploration, underwater archaeology, and marine biology studies.

Why It Is Useful: Jet drives are compact hand are smooth propulsion, and ROVs and AUVs can be moved through the water with less noise disturbance to the environment.

Facts and Figures:

- Jet-powered ROVs can be used in penetrating ocean depths up to 6,000 meters (19,685 feet), in order to discover, collect samples and study the ocean floor.

- AUVs, intended for oceanography research, have been equipped with jet drive systems to navigate with much greater accuracy when, for instance, mapping the seafloor or viewing coral reefs..

- Jet drives provide a noisier mode of propulsion, which is best suited for underwater research because it reduces the disturbance to marine life.

Future Potential and Innovations in Jet Drive Technology

Jet drive technology has become a rather popular option in the use for many boats, personal watercraft, and even militaries around the globe, but greater potential remains to be had in jet drive technology itself.

More demanding are growing to require greener, efficient propulsion systems, thereby making jets become far more powerful, as well as a bit more sustainable while being easily adapted.

This can mean innovative electric motors, hybrid systems, and smarter designs, just to name a few of the exciting possibilities. The implications go beyond recreational boating alone, with future implications in environmental rescue, military operations, and underwater exploration.

Some of the Main Innovations and Future Trends includes:

- Electric jet drives will become a reality. With them, emissions and noise will be lessened, and it can now mean a cleaner and quieter boating experience.

- Jet drives are most commonly associated with high-speed boats and personal watercraft, but did you know they have many other uses beyond just marine propulsion? From military vessels to environmental rescue operations, jet drive technology has proven to be incredibly versatile. In fact, jet drives are known for their efficiency, maneuverability, and ability to operate in shallow waters, making them ideal for a wide range of industries. Have you ever wondered how jet drives are transforming fields like underwater exploration or even luxury watercraft? In this article, we will explore the surprising and diverse applications of jet drive technology across various sectors, showcasing its growing importance in modern technology. How do Jet Drives work? A jet drive is the form of propulsion used by a boat or watercraft to push themselves in the water. This can work by taking in water and pushing it out at high speed, allowing them to move forward. So, how do jet drives actually work? Here’s a breakdown of how jet drives work, step by step: 1. Water Ingestion The process of water being sucked into a boat is through an intake located at the bottom of its hull. The intake is placed in a way that receives a large amount of water as the boat moves along. Why it matters: The speed of the boat determines how much water would be taken in to produce a greater thrust used to push the boat out. 2. Impeller or Pump When water reaches the intake, it is directed towards the impeller, a form of pump, inside the jet drive unit. The impeller is a spinning rotor often made of metal or plastic, which rapidly moves water. How it works: When the impeller rotates, it forces the water into a narrow channel where it increases its speed. The faster the impeller rotates, the more water that is pushed through to create more thrust. 3. Pressurized Water Once the impeller speeds up the water, it moves into a volute (a spiral-shaped casing) that helps to direct the high-speed water flow into a nozzle. The water is now pressurized and traveling fast. Why it's important: This is why the water in the boat can quickly propel the boat forward since pressure and speed make water travel far like a hose if you have the nozzle constricted. 4. Water Ejection: The water is forced out through a nozzle at the back of the boat, but this time, the nozzle is usually adjustable in many systems. The direction of the flow of water is used by the operator to steer the boat. Outcome: At high speed, the exit of the nozzle forces the water backward. It thus pushes the boat forward. 5. Steering and Maneuvering In most jet drive systems, the nozzle can be tilted or rotated to steer the boat. The operator can control the direction of the jet stream, allowing for precise turns and quick maneuvering. This is a key advantage of jet drives over traditional propellers. Why it's cool: Jets can be turned by opening the nozzle, thereby turning the thrust-producing component. They are very sensitive to direction of thrust and wonderful at doing tight turns, making them useful in high-speed or low-speed operations in shoal water, where propellers may not function properly. 6. Safety Advantages Unlike traditional propeller boats, jet drives are safer because there is no exposed spinning blade that can harm people or objects in the water. Intake and nozzle are usually covered by a grating or cover to reduce the risk of injury. 5 Key Uses of Jet Drives in Various Industries Jet drives are versatile propulsion systems that have found applications in many industries beyond traditional watercraft. Here are five key areas where jet drives are being used: 1. Jet Drives in Recreational Watercraft Jet drives are commonly used in personal watercraft such as jet skis, wakeboards, and small boats. These watercraft use the jet drive's power to provide fast acceleration and maneuverability. Why They Are Popular: One major benefit of jet drives on leisure boats is that they work even in shallow waters without exposing the propeller and the damage it could potentially take. They also afford superior control and are more safe because they don't expose blades. Facts and Figures Jet skis reach a speed of as much as 65 mph, or 105 km/h, due to jet propulsion. Jet drive-powered boats are very ideal for watersports like wakeboarding. It makes response faster and handling smooth. Jet-driven watercraft can operate in just 6-12 inches of water, making them great for shallow areas. Jet drives have no exposed propeller, reducing injury risks. New jet drive models are quieter and meet stricter noise regulations. 2. Jet Drives in Military and Defense Applications Jet drives are used for fast assault boats, amphibious vehicles, and reconnaissance vessels in the military. The boats must be speedy, agile, and must operate in shallow waters. Why Its useful: Jet drives provide military vessels the capacity to attain high speeds, still managing stealth due to the noise levels lower than traditional propellers. Also, the launch time is quite faster, and navigating shallow territories such as marshes or rivers is very easy. Facts and Figures Jet drives provide for rapid transitions between land and water, perfect for amphibious assault vehicles. Jet drives are not noisy and can be stealthy because of their silence, which can never be detected easily. It uses jet-driven rescue boats to quickly get out of flooded regions or hostile terrains. Jet drive boats are manufactured to withstand aggressive conditions, so they do not hesitate to operate when extreme weather or rough sea conditions arrive. 3. Jet Drives for Commercial and Industrial Applications Jet drives are also used in large commercial vessels, including ferries, cargo ships, and passenger boats. Their usage includes industrial watercraft such as dredgers and service boats. Why It Matters: Jet drives provide better fuel efficiency and maneuverability, especially in congested or confined spaces like ports or narrow channels. They also reduce the chances of getting damaged by underwater obstructions. Facts and Figures Jet drives can be efficient during dredging operations to push through shallow and debris-laden waters, something that propeller-driven boats could not do. Industrial boats, such as dredgers and tug boats, use jet drives primarily for better maneuverability while operating in busy harbors. Jet drives are preferred in demanding commercial and industrial conditions due to their ability to operate reliably in harsh weather and rough waters. 4. Jet Drives in Environmental and Rescue Operations Jet drives are used for rescue boats and environmental monitoring vessels. Its ability to navigate in shallow and challenging water makes it ideal for search-and-rescue missions, oil spill responses, and environmental surveys. Why It Matters: Jet-drive boats can go faster and navigate into narrower spaces than other types of boats to reach disaster zones in emergency situations. In addition, they are used for oil spill recovery because they avoid sensitive ecosystems. Facts and Figures In the case of oil spill response, jet drive-powered boats can operate at a water depth of as little as a few inches, which makes them ideal for reaching contaminated shorelines. Rescue operations in flood-prone areas often employ jet-powered boats to navigate flooded streets or marshlands, saving time compared to traditional vehicles. Sharp turns and rapid direction changes are crucial in rescue operations, particularly in crowded or narrow waterways. 5. Jet Drives for Underwater Exploration and Research Jet drives are also used in Remotely Operated Vehicles and Autonomous Underwater Vehicles. They are deployed by scientists for deep-sea exploration, underwater archaeology, and marine biology studies. Why It Is Useful: Jet drives are compact hand are smooth propulsion, and ROVs and AUVs can be moved through the water with less noise disturbance to the environment. Facts and Figures: Jet-powered ROVs can be used in penetrating ocean depths up to 6,000 meters (19,685 feet), in order to discover, collect samples and study the ocean floor. AUVs, intended for oceanography research, have been equipped with jet drive systems to navigate with much greater accuracy when, for instance, mapping the seafloor or viewing coral reefs.. Jet drives provide a noisier mode of propulsion, which is best suited for underwater research because it reduces the disturbance to marine life. Future Potential and Innovations in Jet Drive Technology Jet drive technology has become a rather popular option in the use for many boats, personal watercraft, and even militaries around the globe, but greater potential remains to be had in jet drive technology itself. More demanding are growing to require greener, efficient propulsion systems, thereby making jets become far more powerful, as well as a bit more sustainable while being easily adapted. This can mean innovative electric motors, hybrid systems, and smarter designs, just to name a few of the exciting possibilities. The implications go beyond recreational boating alone, with future implications in environmental rescue, military operations, and underwater exploration. Some of the Main Innovations and Future Trends Electric jet drives will become a reality. With them, emissions and noise will be lessened, and it can now mean a cleaner and quieter boating experience. Hybrid jet drives, combining electric motors with traditional engines, will be more fuel efficient, have a longer range, and have a reduced environmental footprint. Future jet drives will include better pump designs, better materials, and smarter technology to make boats more efficient even in challenging waters like ice or shallow areas. The Jet drives will be packed with more advanced sensors and digital controls to enhance both efficiency and safety in fuel consumption for user experience. The use of sustainable materials and biodegradable component-based jet drive systems is essential in reducing its makers' environmental footprint. These innovations would lead to an increasing demand for jet drives in applications with better performance, sustainability, and versatility in many uses. FAQs Can Jet Drives be used in Electric-Powered Boats? Yes Electric-powered boats are now using jet drives for propulsion. Electric jet drives are quieter, cleaner, and more efficient than gasoline engines, making electric-powered jet boats perfect for ecologically friendly boating. The market will now hold a great number of electric jet boats as more innovative technologies arise. Are Jet Drives Safe for Recreational Boating? Yes, jet drives are safer than traditional propeller systems for recreational boating. Since there are no exposed propellers, it reduces the risk of injury, making them a good choice for family outings, watersports, and boating in busy areas with swimmers. Final words Jet drives have proven to be versatile, far beyond recreational boating. They are applied in military operations for fast, maneuverable vessels and in search-and-rescue missions because of their ability to navigate shallow, debris-filled waters. Jet drives are also essential in environmental cleanups, helping contain oil spills with minimal disruption. Indeed, many search-and-rescue operations depend on jet-driven boats to quickly access areas that might be difficult to reach otherwise. As technology evolves, so will electric jet drives; therefore, they are quieter and more environmentally friendly. There is much potential for the future of jet drives and their use in the coming years across all industries. Let's explore the power of jet drives together. Learn now! Hybrid jet drives, combining electric motors with traditional engines, will be more fuel efficient, have a longer range, and have a reduced environmental footprint.

- Future jet drives will include better pump designs, better materials, and smarter technology to make boats more efficient even in challenging waters like ice or shallow areas.

- The Jet drives will be packed with more advanced sensors and digital controls to enhance both efficiency and safety in fuel consumption for user experience.

- The use of sustainable materials and biodegradable component-based jet drive systems is essential in reducing its makers' environmental footprint.

These innovations would lead to an increasing demand for jet drives in applications with better performance, sustainability, and versatility in many uses.

FAQs

Can Jet Drives be used in Electric-Powered Boats?

Yes Electric-powered boats are now using jet drives for propulsion. Electric jet drives are quieter, cleaner, and more efficient than gasoline engines, making electric-powered jet boats perfect for ecologically friendly boating. The market will now hold a great number of electric jet boats as more innovative technologies arise.

Are Jet Drives Safe for Recreational Boating?

Yes, jet drives are safer than traditional propeller systems for recreational boating. Since there are no exposed propellers, it reduces the risk of injury, making them a good choice for family outings, watersports, and boating in busy areas with swimmers.

Final words

Jet drives have proven to be versatile, far beyond recreational boating. They are applied in military operations for fast, maneuverable vessels and in search-and-rescue missions because of their ability to navigate shallow, debris-filled waters.

Jet drives are also essential in environmental cleanups, helping contain oil spills with minimal disruption. Indeed, many search-and-rescue operations depend on jet-driven boats to quickly access areas that might be difficult to reach otherwise.

As technology evolves, so will electric jet drives; therefore, they are quieter and more environmentally friendly. There is much potential for the future of jet drives and their use in the coming years across all industries.

Posted by Brian Whiteside