Springtime Boat & Outboard Checklist

Posted by Frank Abagnale Jr. on 22nd Mar 2024

Springtime Boat & Outboard Checklist

Spring will be here sooner or later even if doesn’t seem like it right now. When spring comes and the walleye bite on the river gets going or, like me, if you wait for opening weekend, you’ll want to make sure your outboard is ready and raring to go!

After a long winter’s nap, there are some things that need to be checked before your outboard ever sees the water.

Click HERE to install the FISHBRAIN Fishing & Tool App

Some things have been done if you properly winterized your outboard, but after hibernating for a few months, things can happen.

You don’t have to be a genius mechanic or even be mechanically inclined. Follow these steps, and you’ll be ready to hit the water!

Start with checking the fluids.

Oil System

First, check for water in your oil, air in your oil lines, and debris in your oil tank. Many oil tanks on the engine have a sight tube for water to collect or a low spot to see if there is water. You can also just look to see if you can see a separation line in your tank. To do this you may have to loosen you tank and tip it on its side to get any water that may be present to run to one corner and collect together.

This is also a time to look for debris. Sometimes I have witnessed the plastic seal, which has come off a bottle of oil to keep it from spilling when on the shelf at the store, get in the oil system and completely block the oil flow. This can easily cause outboard powerhead failures.

Almost all Mercury and Yamaha outboards have clear oil lines allowing you to see that it is all oil with no air or gas in the line. If a check valve goes out on a Mercury engine, it can actually back-feed fuel into the oil system. I have seen it push oil all the way back through the pump and into the small engine mounted oil tank.

This can cause severe engine damage if not repaired properly. You can normally look at the oil line and see either air or fuel in it instead of oil. Take a close look at the lines and make sure they are not cracked because, over time, they dry out and will break in half causing severe engine damage.

Also do a visual check for any leaks in any of the oil system. Now is also a good time to make sure you didn’t miss any grease zerks in the fall on your outboard as well. Normally there are one or two on the tilt/steering tube and one or two on the pivot tube.

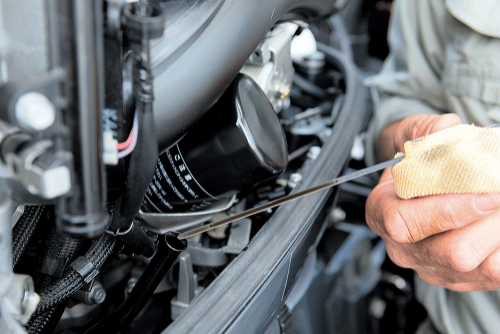

If you see water or debris you will want to remove it. Some oil systems have oil filters on them and this is also a great time to change that if it’s been a while or if you’ve never done it before. Now that you know you have good oil going to the engine, make sure your oil lines are full of oil.

Unwelcome Visitors

Check to see if there were mice or other critters taking refuge in your outboard over the winter. If you find any of these unwelcome visitors, kick them out and check for any damage. For some reason, one of a mouse’s favorite foods, seems to be wire coating.

I have also seen them go through the prop hub up the mid-section and build a nest in a cylinder. This is a VERY bad thing, but as long as your engine was properly fogged, you won’t have to worry about it, as mice don’t enjoy lying on oil.The only way to check for this, other than cranking the engine, is to pull the spark plugs and look for evidence of mice. This is also a good time to change the spark plugs anyway.

Fuel System

Inspect your fuel system for leaks or damage. Check hose connections and tank surfaces. If you see any signs of softness or cracking, replace the damaged components. Ensure all fittings and clamps are secured. Confirm that your engine exhaust and ventilation systems are in functioning order. Service your seawater pumps every other year. If in doubt, then do it now. Finally, check your owner’s manual for any specific instructions on starting your engine after winter storage.

If you forgot to stabilize it, I would recommend starting with fresh fuel in your tanks. This is also a great time to change out or clean your fuel filters on your boat and in your engines fuel system. The highly advanced fuel systems we have today do not do well with contaminates, like water or debris, whether it be from the gas station or filings from the inside of a new fuel tank.

There are a lot of fuel filters now a days and some of them require some tear down to get into different parts of the fuel systems to replace them.

Belts, Cables and Hose

Examine belts, cables and hoses as they can become brittle and crack during winter storage. Verify that the belts fit tightly around pulleys and are not worn. Swells and cracks on the outer jacket of the throttle, shift and steering control cables could indicate internal corrosion. Replace as necessary.

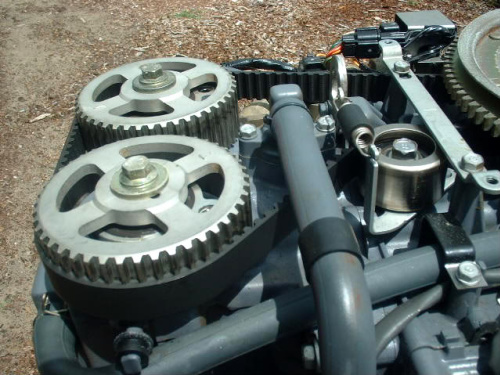

Belt maintenance does not just apply to four strokes. There are several models of two strokes that have belts that require maintenance for optimal performance as well. A Mercury Optimax and a Yamaha HPDI both have belts running part of their fuel system. If a belt breaks, your engine will not run as well as it should.

These belts should be checked and adjusted periodically. It is recommended to replace them every 1000 hours or 5 years. That is the same time frame on a Yamaha four stroke as well. Timing belts are supposed to be replaced every 1000 hours or 5 years as well. You can get more time out of them but if you wait too long, and your belt breaks, you more than likely will cause severe engine damage.

In fact, this situation will more than likely result in complete powerhead failure. This is something that I don’t think a lot of people think about but many of these engines don’t run a timing chain like many car engines. They run a cogged belt that stretches and breaks down over time which is why it will need to be changed now and then.

Electrical Systems

The electrical system’s job is to carry voltage from one place to another. If the voltage can’t make the journey, or if it’s diminished when it gets there, the receiving device will not function properly, if at all. The goal is to have as much voltage (or electrical energy) arrive at Point B as left Point A.

As electricity passes through a device, some parasitic loss is normal. However, corrosion impedes electricity’s ability to travel, which can cause significant voltage loss or intermittent voltage. Either can wreck the good times, but with simple visual inspections and physical actions these scenarios can usually be avoided.Inspect for tight corrosion free connections. Charge the battery and test it to make sure it maintains a charge. Use a stainless-steel lock nut to prevent cables from loosening up.

- Inspect the batteries. If corrosion is evident, remove and clean terminals with baking soda solution, clean cable ends and reconnect.

- Load test all batteries.

- Check the battery switches to be sure they are functional. Older models can wear out.

- Inspect battery cable connections to each switch.

- Check breakers and/or fuse panels.

- Inspect bus bars for corrosion. Wire brush clean if needed.

- Check all helm switches including trim tabs, power trim and tilt to be sure they are operational.

- Check all lights. If you’ve planned on switching over to LEDs, this is a good time

- Check all navigational, sonar and communications electronics to be sure they are operational. Pay specific attention to connections to be sure they are tight. Radio antenna connections are notorious for corroding. Inspect all wires and cables.

- Make sure the automatic bilge pump float switch works correctly.

Finally, replace any burnt out light or console bulbs.

Trim Tabs

Inspect the trim tabs, screws, bolts and rams. If you keep the boat in the water the trim tabs should be treated with an antifouling coating seasonally. Check the hydraulic cylinders for any sign of leakage. Inspect the hydraulic lines, the pump and fluid reservoir. Top off with the recommended fluid if needed.

Steering System

Non-power assisted systems have a small fill cap on the pump body behind the steering wheel. Power assist systems are checked at the pump reservoir. Check fluid level and top off as needed. Inspect all hydraulic hose connections to be sure they are tight and there are no leaks. If it was necessary to remove any steering lines or replace the ram end caps at the engine, the system will have to be bled.

Fluid Levels

Check all your fluid levels, including power steering, power trim reservoirs, coolant and engine oil. If you didn’t change the engine oil during the winterization process, you’ll want to do that now. Examine the bilge area for fluid leaks. Check lines for cracking and replace damaged parts. If you used anti-freeze in your fresh water tank, be sure to flush it out and disinfect the system before connecting the pump to the water lines.

Hulls and Propellers

While inspecting the hull, look for blisters distortions and cracks. Clean the hull, deck and topsides using an environmentally safe cleaning solution. Touch up any areas where the paint is looking worn. Wax the hull to preserve the paint – it can extend the life of your paint by two or three seasons.

Clean windows, canvas, Bimini and dodger. If mold or mildew have snuck under your cover, scrub accordingly. You’ll want to use protective gear to avoid getting spores on your skin.

Safety Gear

Check your jackets – make sure they are in good condition and that you have enough and the right sizes for all potential passengers. Examine your fire extinguishers, are they full charged? Make sure you have the correct class and quantity for your vessel. If you have an enclosed area, install a working carbon monoxide detector. If you have an EPIRB (Emergency Position Indicating Radio Beacon) run it through your regular testing and maintenance. If you don’t have one, consider acquiring one to alert search and rescue in the event of an emergency.

- Inspect all PFDs and throwable life rings aboard for mildew. Clean if needed.

- For inflatable PFDs, check charging system.

- Inspect all flares, paying attention to expiration dates. If expired, purchase replacements.

- Inspect the life raft, checking for required inspection date. Bring it in to a certified service facility if needed.

- Check to see if fire extinguishers are fully charged and take a look at their physical condition.

- Conduct a safety check of all EPIRB and PLB units to be sure they are operational and to check the battery integrity.

- Review the literature to see when battery replacement is recommended by the manufacturer.

- Conduct a safety check of the emergency S.O.S. system on the VHF radio if applicable.

General Vessel Systems

- Inspect all thru-hull fittings from inside and outside the boat.

- Check all thru-hull shut-off valves to be sure they are working.

- Lubricate if necessary, replace if frozen. Inspect all hoses from thru-hull fittings.

- Be sure they are all double-clamped and that the clamps are not corroded.

- Check bilge pumps and automatic bilge pump switches.

- Check additional pumps (washdown; macerator; etc.).

- Inspect your anchor line for wear around the thimble linking it to the chain or anchor.

- Check the shackles to be sure the screw is not rusted tight.

- Remove the line from the anchor locker and inspect.

- Clean anchor locker while empty.

- Inspect outer hull for chips, dings, gelcoat blisters. Repair as needed.

- Inspect hardtop/t-top pipes as welds can break with age and hard vessel use.

- Inspect places where wires enter and exit the piping in case grommets are bad or missing, which can cause chafing.

- Inspect the sanitation system (head and holding tanks) where applicable to be sure they are working.

- Remove antifreeze if it was winterized.

- Remove antifreeze from the freshwater system where applicable, flush with clean, fresh water and refill.

If you run into any problems or tasks you may find outside your comfort zone, bring the boat into a professional who can safely address them.

The United States Coast Guard also has a mobile app available that allows you to request a vessel safety check from the U.S. Coast Guard Auxiliary and can determine what safety equipment you are required to carry by law.

Starting an Outboard Motor After a Long Storage

If you are in need of used, remanufactured or new parts for your outboard or sterndrive Marine Parts Warehouse can quickly get you ready for spring.